The latest “china trade deal” confirms that the United States will continue purchasing goods from China, providing renewed clarity and stability for global procurement teams. From a sourcing and cost-management perspective, this agreement reopens critical opportunities that had been threatened by uncertainty, tariff escalation, and geopolitical tension. For companies that rely on China for manufacturing, raw materials, or components, the ability to continue purchasing under a more predictable framework is a major strategic advantage.

Below is a procurement-focused analysis explaining what this agreement means, why it matters, and how organizations should adjust their purchasing strategies under the renewed US-China trade environment.

What Does the China Trade Deal Mean for Procurement?

The new “china trade deal” ensures that supply chains dependent on China can continue functioning without sudden disruptions. For procurement professionals, the agreement influences three major areas:

Cost predictability (tariffs become stable or reduced)

Supply continuity (purchases from China can proceed as usual)

Long-term planning reliability (lower geopolitical risk)

This stability is vital for sectors such as electronics, automotive components, textiles, industrial machinery, and consumer goods—industries where China remains a dominant supplier.

A Major Reduction in Procurement Risk

Before the agreement, buyers faced constant uncertainty:

Would tariffs rise again?

Would access to China be restricted?

Would suppliers be forced to relocate or shut down export operations?

The china trade deal alleviates these fears by clearly stating that US companies may continue purchasing Chinese goods. This reduces:

Supply chain risk

The likelihood of supply chain disruptions is reduced, and companies no longer need to frequently adjust suppliers or backup plans.

Contract renegotiation pressure

The suspension of tariffs reduces cost pressures and alleviates the pressure of renegotiating many contracts.Price adjustments, default risks, and delivery delays that were previously caused by tariff increases will decrease.

Emergency sourcing costs

Reduced supply uncertainty means businesses no longer need to stockpile large inventories or make emergency cross-border requisitions.

During this phase, many companies will need to recalibrate their supply chain structure. If the team lacks in-depth understanding of the Chinese supply market, they can also leverage professional procurement partners to assist with supplier price comparisons, factory audits, and cross-border logistics arrangements to ensure no supply disruptions or cost discrepancies occur during the transition.

Stabilized or Lower Tariffs Improve Total Cost of Ownership (TCO)

The agreement signals fewer tariff increases and, in some categories, potential tariff rollbacks. For procurement teams, tariff stability allows:

More accurate landed cost calculations

Clearer budgeting

Increased purchasing volume when pricing becomes favorable

With cost volatility reduced, buyers can better leverage China’s manufacturing scale and competitive labor structures to maintain lower TCO.

If a company doesn’t have a dedicated team to handle local procurement in China, outsourcing to an experienced third-party procurement agency or local purchasing agent is a common choice. They can directly connect with factories, control quality, and assist with international logistics arrangements, reducing cross-border communication costs and supply chain risks.

Supplier Relationships Strengthen Under Renewed Clarity

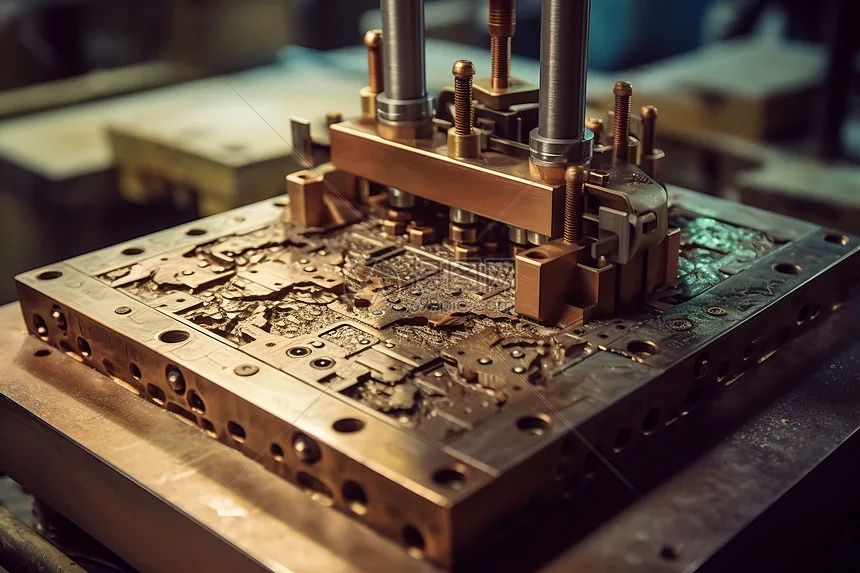

Long-term supplier partnerships in China were strained during the period of heightened trade tensions. Many suppliers hesitated to:

Commit to long-term pricing

Expand factory capacity

Invest in tooling or dedicated production lines

Now that the china trade deal confirms continued purchasing, suppliers regain confidence. This benefits procurement by enabling:

Multi-year contract agreements

Better pricing tied to volume guarantees

Increased willingness to co-invest in new product development

Procurement Strategy Can Return to Optimization Instead of Emergency Flexing

During trade uncertainty, procurement teams were forced to divert resources into tasks such as:

Developing backup suppliers outside China

Splitting production among multiple countries

Rewriting contracts to include tariff escalation clauses

With the new agreement, teams can refocus on optimization, such as:

Cost reduction projects

Supplier consolidation

Inventory optimization

Improving supplier performance KPIs

Organizations can strategically evaluate sourcing locations again instead of making defensive decisions.

Continued Access to China Preserves the Advantages of Global Sourcing

China remains unmatched in:

manufacturing scale,

component availability,

logistics maturity,

specialization clusters (electronics, plastics, metals, textiles),

and competitive pricing.

By reaffirming access to Chinese suppliers, the china trade deal ensures that companies can continue benefiting from:

Shorter lead times compared with alternative markets

Robust supply ecosystems

Reliable quality control standards

Lower transition costs (no need to move production elsewhere)

Moving sourcing away from China often increases costs by 15–30%. The agreement allows procurement teams to avoid this unnecessary disruption.

How Should Procurement Teams Respond to the New China Trade Deal?

Optimize pricing negotiations

Use tariff stability as leverage to request:

pricing resets,

volume-based discounts,

or long-term cost-down agreements.

Strengthen SRM (Supplier Relationship Management)

Rebuild partnerships with Chinese suppliers through:

long-term contracts,

joint planning,

improved forecasting transparency.

In addition, with the increased stability brought by the agreement, more and more companies tend to cooperate with people who are familiar with the local Chinese supply chain ecosystem. For example, professional sourcing services can quickly screen suppliers, complete sample testing, supervise shipments, and match the best logistics solutions, saving companies a significant amount of time and communication costs.

Reassess global sourcing strategies

Those who shifted parts of their supply chain to Vietnam, India, or Mexico should reconsider:

actual cost competitiveness

logistics efficiency

supplier maturity

With China back on stable footing, blended strategies may outperform full diversification.

In the new US-China trade environment, businesses need more professional partners who understand supply chains, cost structures, and cross-border logistics. If you are looking for support in local sourcing in China, factory audits, sample testing, or international logistics integration, contact us for professional procurement services to help you reduce procurement costs and improve delivery stability.