Low cost country sourcing risks are the hidden challenges companies face when purchasing goods from countries with lower labor and production costs. While sourcing from regions such as China, Vietnam, India, or Bangladesh can significantly reduce unit costs, it also introduces risks that can impact quality, delivery, compliance, and brand reputation.

Many procurement teams focus on price savings but underestimate low cost country sourcing risks—which can quickly erase cost advantages if not properly managed.

If your business is sourcing from low-cost countries and wants to reduce risk without losing cost competitiveness, having experienced local sourcing support is critical.

What Is Low Cost Country Sourcing (LCCS)?

Low cost country sourcing (LCCS) refers to procuring goods or components from countries where manufacturing and labor costs are significantly lower than domestic markets.

Common LCCS Countries

- China

- Vietnam

- India

- Bangladesh

- Indonesia

- Mexico (for nearshoring)

While cost savings are attractive, low cost country sourcing risks increase as supply chains become longer, less transparent, and harder to control.

Cost advantage without control often leads to operational and reputational risk.

10 Major Low Cost Country Sourcing Risks

1. Quality Control Problems

One of the most common low cost country sourcing risks is inconsistent quality.

Causes include:

- Weak internal QC systems

- Subcontracting without disclosure

- Poor raw material control

Without on-site inspections, defects are often discovered only after goods arrive, when correction costs are highest.

Independent inspections and factory audits are often the most effective way to control this risk.

👉 Contact us for factory audits and quality inspections

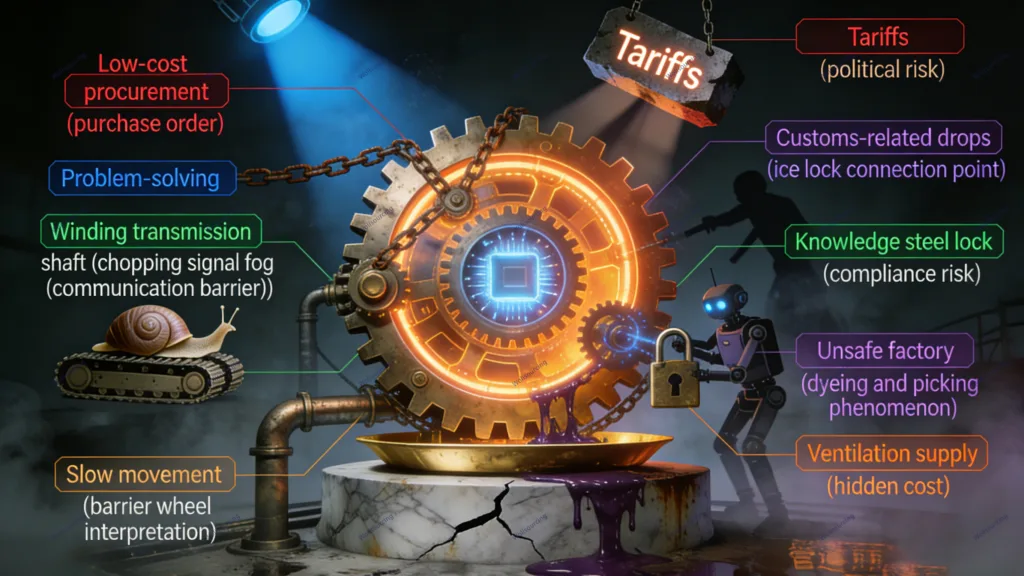

2. Communication & Language Barriers

Misunderstandings in specifications, tolerances, or packaging can lead to costly errors.

Even small communication gaps can result in:

- Incorrect materials

- Wrong labeling

- Non-compliant packaging

This is a frequent issue in offshore sourcing, especially when buyers rely solely on email or messaging platforms.

3. Longer Lead Times & Delays

Distance adds risk.

Factors impacting delivery include:

- Production delays

- Port congestion

- Customs clearance issues

- Shipping disruptions

Longer lead times reduce supply chain agility and increase inventory holding costs.

Local follow-up during production can significantly reduce delay-related risks.

4. Compliance & Regulatory Risks

Failure to meet regulations is one of the most expensive low cost country sourcing risks.

Examples include:

- Safety standard violations

- Environmental non-compliance

- Missing certifications (CE, FCC, FDA, REACH)

Non-compliance can result in shipment seizures, fines, or forced recalls.

Compliance checks should happen before production—not after shipment.

👉 Discuss compliance and certification support with our team

5. Intellectual Property (IP) Theft

IP protection is a major concern in global sourcing.

Risks include:

- Design copying

- Unauthorized production

- Brand misuse

This risk increases when tooling, molds, or designs are shared without proper legal safeguards.

6. Hidden Costs That Reduce Savings

A low unit price does not equal a low total cost.

Hidden costs often include:

- Quality rework and returns

- Inspection and re-inspection fees

- Expedited shipping

- Inventory carrying costs

- Warranty and after-sales claims

These hidden costs frequently outweigh the original savings.

Total cost of ownership (TCO) analysis is essential in LCCS decision-making.

7. Supplier Reliability & Financial Stability

Some low-cost suppliers operate with very thin margins.

Risks include:

- Sudden factory closures

- Inability to scale production

- Raw material shortages

Supplier failure can disrupt your entire supply chain overnight.

8. Ethical & Social Compliance Risks

Modern consumers expect ethical sourcing.

Risks include:

- Unsafe working conditions

- Child labor

- Excessive overtime

Violations can severely damage brand reputation and lead to long-term trust loss.

Ethical audits are increasingly expected by global buyers and retailers.

9. Political & Geopolitical Risks

Trade policies and global politics directly affect sourcing.

Examples include:

- Tariffs and trade wars

- Sanctions

- Export restrictions

These uncontrollable factors are critical low cost country sourcing risks—especially for single-country sourcing strategies.

10. Limited Supply Chain Visibility

Lack of transparency makes risk management difficult.

Common issues include:

- Unknown subcontractors

- Poor traceability

- Limited production reporting

Without visibility, problems escalate before they’re detected.

On-the-ground sourcing partners can significantly improve transparency and control.

👉 Learn how we improve supply chain visibility

How to Reduce Low Cost Country Sourcing Risks

The goal is not to avoid LCCS—but to manage it correctly.

Risk Mitigation Strategies

- Use qualified sourcing agents

- Conduct factory audits

- Implement third-party inspections

- Diversify suppliers (avoid single-source dependency)

- Clearly document specifications and contracts

Organizations that invest in risk management consistently outperform those focused only on price.

Role of Procurement Process in Risk Control

A structured procurement process significantly reduces low cost country sourcing risks.

Best Practices

- Supplier pre-qualification

- Total cost of ownership (TCO) analysis

- Performance scorecards

- Regular audits and reviews

Strong procurement governance turns sourcing from a vulnerability into a competitive advantage.

Are Low Cost Country Sourcing Risks Worth Taking?

Yes—when managed correctly.

Companies that successfully control low cost country sourcing risks achieve:

✔ Lower production costs

✔ Scalable supply chains

✔ Access to global manufacturing expertise

Those who ignore the risks often face quality failures, recalls, and reputational damage.

Low Cost Country Sourcing Risks vs Benefits

| Benefits | Risks |

|---|---|

| Lower unit costs | Quality variability |

| High production capacity | Longer lead times |

| Supplier variety | Compliance challenges |

| Scalability | Political uncertainty |

Balanced, informed decision-making is essential.

Global Standards & Risk Frameworks

International organizations provide guidance on sourcing risk management, including WTO frameworks and ISO supply chain standards. These frameworks help companies align sourcing practices with global best practices.

Final Thoughts: Managing Low Cost Country Sourcing Risks Strategically

Low cost country sourcing risks are real—but manageable. The companies that succeed in global sourcing are not those who chase the lowest price, but those who balance cost, quality, compliance, and resilience.

With the right suppliers, inspections, contracts, and procurement processes, low cost country sourcing can remain a powerful driver of growth rather than a source of disruption.

👉 Contact us to discuss risk-controlled global sourcing solutions