Procurement process improvement is the systematic effort to make purchasing faster, cheaper, more transparent, and more strategic. In today’s competitive environment, procurement is no longer just about buying at the lowest price—it directly impacts profitability, risk management, and supplier performance.

Organizations that invest in procurement process improvement consistently achieve lower costs, better supplier relationships, and stronger compliance. Whether you’re a small business or a global enterprise, optimizing procurement delivers measurable ROI.

What Is Procurement Process Improvement?

Procurement process improvement involves analyzing, redesigning, and automating procurement activities to eliminate inefficiencies and add value.

Core Objectives

- Reduce purchasing costs

- Shorten procurement cycle times

- Improve supplier quality and reliability

- Increase transparency and compliance

- Align procurement with business strategy

It focuses on the entire procurement lifecycle—from demand planning to supplier payment.

Many organizations understand these objectives but struggle with execution, especially when sourcing from overseas suppliers.

👉 Talk to a sourcing expert about improving your procurement process

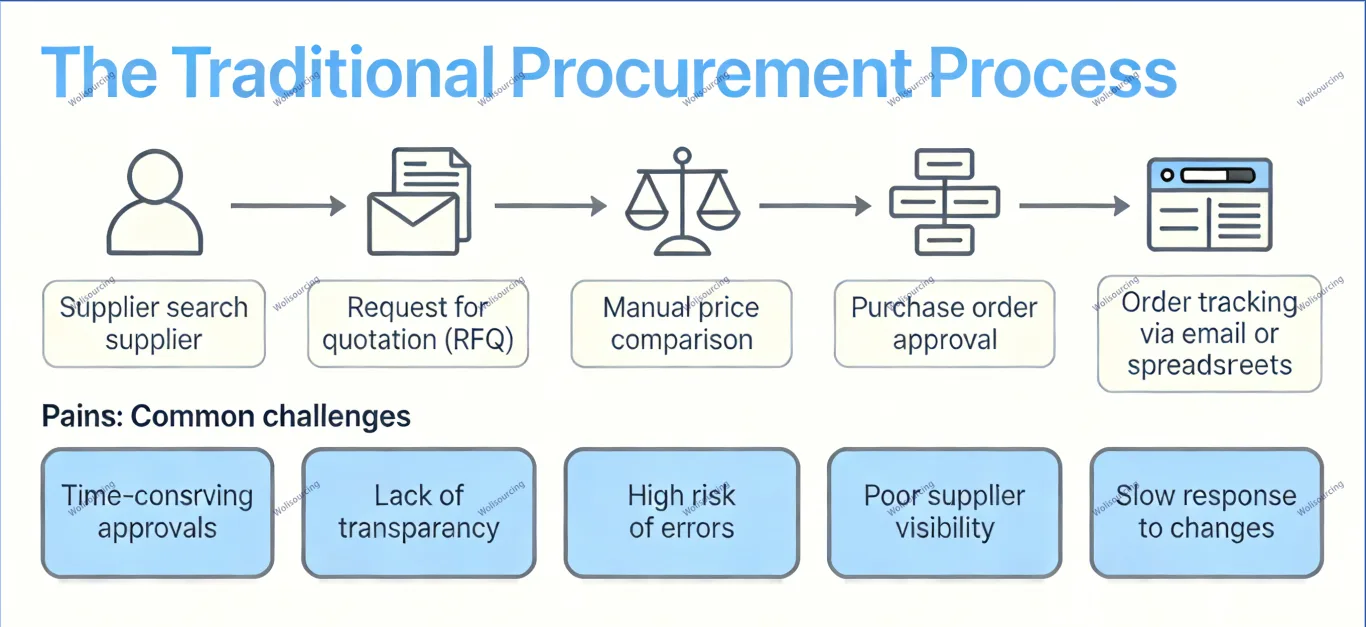

The Traditional Procurement Process (Quick Overview)

Understanding the baseline is essential before starting procurement process improvement.

Typical steps include:

- Need identification

- Purchase requisition

- Supplier sourcing

- Request for quotation (RFQ)

- Supplier selection

- Purchase order creation

- Goods receipt

- Invoice processing & payment

Many organizations struggle with manual steps, approval bottlenecks, and poor data visibility at each stage—particularly when managing multiple suppliers or cross-border sourcing.

10 Powerful Strategies for Procurement Process Improvement

1. Standardize Procurement Procedures

Standardization is the foundation of procurement process improvement.

Benefits:

- Reduces errors

- Improves compliance

- Speeds up approvals

Create clear SOPs for requisitions, approvals, and supplier onboarding.

Standardized processes are especially critical when working with multiple manufacturers or sourcing agents.

👉 Get support building standardized sourcing workflows

2. Centralize Purchasing Activities

Decentralized buying leads to maverick spending.

Central procurement enables:

- Better price negotiation

- Volume discounts

- Stronger supplier control

This is one of the fastest ways to achieve cost savings, especially in high-spend categories.

3. Leverage Strategic Sourcing

Strategic sourcing focuses on long-term value, not just price.

Key elements include:

- Spend analysis

- Supplier market research

- Total cost of ownership (TCO)

Strategic sourcing is a critical pillar of procurement process improvement.

Many companies know the concept of strategic sourcing but lack reliable supplier data and market benchmarks.

4. Automate Procurement with Technology

Digital tools dramatically improve efficiency.

Common solutions include:

- E-procurement systems

- Spend analytics platforms

- Supplier management software

Leading platforms such as SAP Ariba help organizations automate workflows and gain real-time insights.

Technology works best when combined with practical sourcing execution and supplier management.

👉 See how we combine systems with real-world sourcing support

5. Reduce Approval Bottlenecks

Too many approval layers slow down procurement.

Improvement tips:

- Set approval thresholds

- Use automated workflows

- Delegate authority where possible

Streamlining approvals directly improves cycle time and supplier responsiveness.

6. Improve Supplier Management

Supplier performance directly affects procurement outcomes.

Focus on:

- Supplier scorecards

- Regular performance reviews

- Clear KPIs (quality, delivery, cost)

Strong supplier relationships are central to sustainable procurement process improvement.

Effective supplier management often requires on-the-ground communication and verification.

7. Enhance Data Visibility & Spend Analysis

You can’t improve what you can’t measure.

Use data to:

- Identify high-spend categories

- Spot contract leakage

- Detect maverick buying

Spend analytics often uncovers 8–17% hidden savings.

8. Strengthen Compliance & Risk Management

Procurement improvements must also reduce risk.

Key actions include:

- Approved supplier lists

- Contract management systems

- Regulatory compliance checks

Frameworks such as ISO standards (e.g., ISO 9001) help formalize controls and processes.

Compliance risks increase significantly when sourcing internationally without proper supplier vetting.

👉 Contact us for supplier verification and compliance support

9. Train Procurement Teams

People drive process success.

Training should cover:

- Negotiation skills

- Cost analysis

- Supplier relationship management

- Digital procurement tools

Well-trained teams multiply the impact of procurement process improvement initiatives.

10. Track KPIs and Continuously Improve

Procurement is never “done.”

Track metrics such as:

- Cost savings

- Cycle time

- Supplier defect rates

- On-time delivery

Continuous improvement ensures long-term value and resilience.

Common Challenges in Procurement Process Improvement

Despite best intentions, organizations often face obstacles such as:

- Resistance to change

- Poor data quality

- Legacy systems

- Lack of executive support

Addressing change management early greatly increases success rates.

External sourcing partners can often help overcome these challenges faster than internal-only initiatives.

Benefits of Procurement Process Improvement

When executed properly, procurement process improvement delivers:

✔ Lower operating costs

✔ Faster purchasing cycles

✔ Improved supplier performance

✔ Better compliance and audit readiness

✔ Increased strategic value of procurement

Procurement shifts from a cost center to a value driver.

Procurement Process Improvement Example (Real-World Scenario)

A mid-sized manufacturing company improved procurement by:

- Working directly with Wolisourcing

- Implementing e-procurement software

- Reducing approval steps from 5 to 2

Results:

- 12% cost reduction

- 30% faster cycle times

- Higher supplier reliability

Similar results are often achieved when procurement optimization is combined with reliable sourcing execution.

Final Thoughts: Building a Smarter Procurement Function

Procurement process improvement is not a one-time project—it’s an ongoing journey. By combining process standardization, technology, data, and people, organizations can unlock significant savings and operational excellence.

In an era of supply chain disruption and rising costs, improving procurement is no longer optional—it’s essential for sustainable growth.

For companies that want to turn procurement strategies into real cost savings, supplier reliability, and risk reduction, having the right sourcing partner makes all the difference.

👉 Contact us to discuss how we can support your procurement and sourcing goals